CATIA V5

MECHANICAL DESIGN SOLUTIONS

CATIA® V5 is the leading product development solution for all manufacturing organisations, from OEMs, through their supply chains, to small independent producers. The range of its capabilities allows CATIA V5 to be applied in a wide variety of industries, such as aerospace, automotive, industrial machinery, electrical, electronics, shipbuilding, plant design, and consumer goods, including design for such diverse products such as jewellery and clothing.

CATIA V5 is the only solution capable of addressing the complete product development process, from product concept specifications through product-in-service, in a fully integrated and associative manner. It facilitates true collaborative engineering across the multi-disciplinary extended enterprise, including:

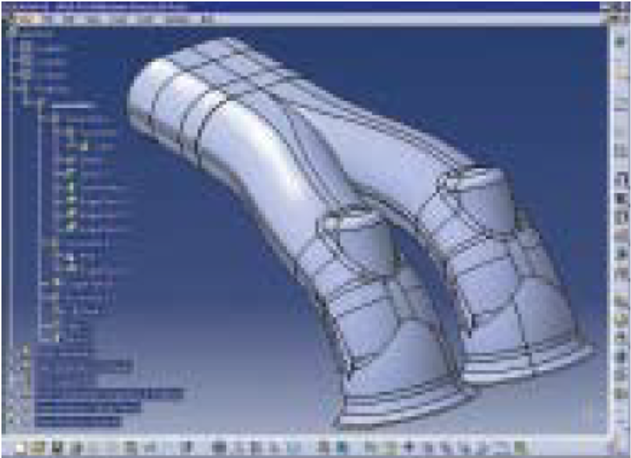

- Style and form design

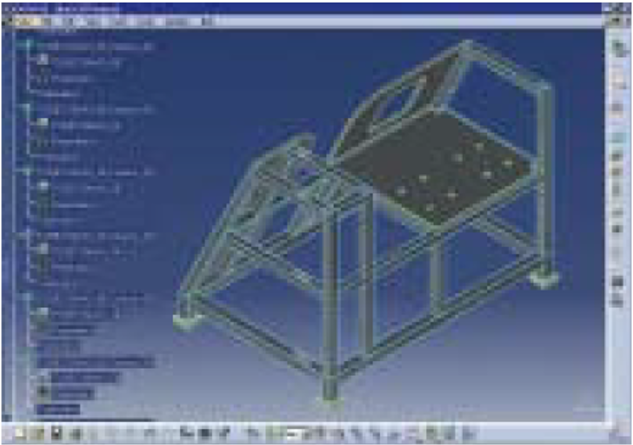

- Mechanical design and equipment and systems engineering

- Managing digital mock-up

- Machining

- Analysis

- Simulation

CATIA products are based on the open, scalable V5 architecture. By enabling enterprises to reuse product design knowledge and accelerate development cycles, CATIA helps companies speed up their responses to market needs and frees end users to focus on creativity and innovation. From concept to detailed design and onto drawing production, CATIA V5 mechanical design solution set accelerates the core activities of product development. Its products also address sheet metal and mold manufacturing requirements through dedicated applications that dramatically enhance productivity and reduce time-to-market.

MAIN HIGHLIGHTS

CONFIGURATIONS

DRAFTING 1

Provides the necessary tools to produce industrial drawings. It includes data interfaces to the most frequently used industry standards, including CADAM drawings.

MECHANICAL DESIGN 1

Provides the tools needed to perform 3D part and assembly design and generate production drawings. In addition, it includes integrated realtimerendering capabilities and supports data exchange using common industry standards, including the CADAM drawing data format.

MECHANICAL ENGINEERING 1

Provides the tools needed to engineer 3D parts and assemblies and generate production drawings. Intuitive stress-testing functions also enable tools for earlier pre-validation of the parts available to all designers. In addition, ME1 includes integrated realtime rendering capabilities and data interfaces to the most common industry standards, including CADAM drawings.

EXTENDED MECHANICAL DESIGN 1

Provides an attractive solution for small and medium enterprises to access the full scope of PLM. XM1 is perfectly suited to various sectors, including industrial machinery or consumer goods. Its 3D product creation package contains comprehensive part and assembly design features, as well as associative drawing extraction capabilities. Designers will also find that it has all the 2D drafting features necessary for efficient drawing production.

To meet industrial-scale needs, the configuration has been reinforced with sheet metal design production capabilities, standard wireframe and surfacing features and dedicated welded assembly design features. In addition, the import and export of IGES and STEP data make collaborative design throughout the extended enterprise very easy. Users managing large assemblies will have particular use for other powerful product analysis features like distance measurement, dynamic sectioning and clash detection.

CORE AND CAVITY DESIGN 2

Provides all necessary tools needed to cover each step of the mold process in one seat. The mold maker would usually have to import some external data using IGES Interface in order to prepare the geometry for CATIA V5 modelling using Healing Assistant. Core and Cavity Design is then used to prepare the part for molding and splitting surfaces.

CV2 also offers wireframe, surface and part features for optimizing surface geometry and improving the ability to manufacture a part on a global scale. This solution is easy to use, fully integrated and highly automated, according to the enterprise requirements.

DRAWING PRODUCTION 2

Provides all the necessary tools to produce industrial drawings in one seat, either from 3D parts or in a pure 2D methodology. As a CATIA P2 configuration, DP2 offers integration tools that are compatible with CATIA V4. It also includes data interfaces to most frequently used industry standards, including CADAM drawings.

MECHANICAL DESIGN 2

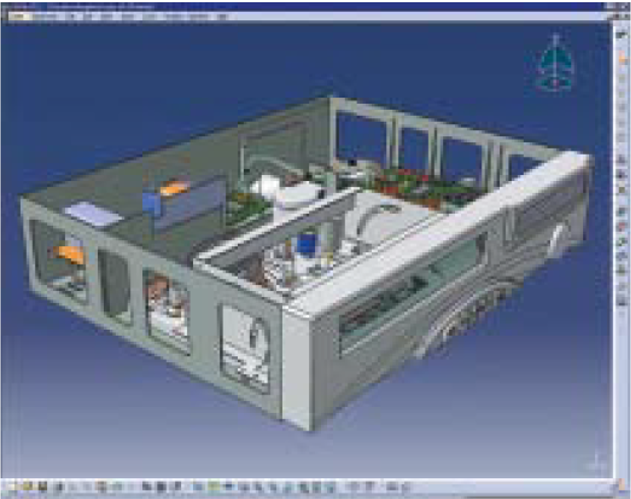

Provides in one seat all the necessary tools to perform advanced 3D design of parts and assemblies in the context of the full scale digital mock-up, and generation of production drawings. In addition, it includes integrated realtime rendering capabilities.

As a CATIA P2 configuration, MD2 offers advanced 3D orientation features, such as fly-through navigation and advanced specification graph display and manipulation. Customers benefit from its built-in interoperability with other CATIA V5 solution sets. It is the configuration of choice for existing CATIA V4 customers because it offers integration tools that are compatible with CATIA V5, as well as data interfaces to the most frequently used industry standards. Customers also benefit from a seat definition that can be seamlessly upgraded by the addition of shape design capabilities, allowing for the design of more complex parts using hybrid-modelling methodologies.

MECHANICAL ENGINEERING 2

Provides in one seat all the necessary tools to perform advanced 3D engineering of parts and assemblies in the context of the full scale digital mock-up, and generation of production drawings. It also includes intuitive stress-testing functions, which makes the early pre-validation of parts available to all designers.

As a CATIA P2 configuration, ME2 offers advanced 3D orientation features, such as fly-through navigation and advanced specification graph display and manipulation. Customers benefit from its built-in interoperability with other CATIA V5 solution sets. It is the configuration of choice for existing CATIA V4 customers because it offers integration tools that are compatible with V4, as well as data interfaces to the most frequently used industry standards. Customers also benefit from a seat definition that can be seamlessly upgraded by the addition of shape design capabilities, allowing for the design of more complex parts using hybrid-modelling methodologies.

MECHANISM SIMULATION 2

Provides all the necessary tools to perform advanced 3D design of parts and assemblies in one seat. DMU Kinematics Simulator 2 (KIN) easily simulates mechanism motion using mouse-based manipulation for the validation of mechanical mock-ups. This is a particularly relevant feature for people involved in activities ranging from the design of mechanisms to the functional verification of mechanical systems.

Customers also benefit from its built-in interoperability with other CATIA V5 solution sets. It is the configuration of choice for existing CATIA V4 customers because it offers integration tools that are compatible with V4.

SHEET METAL DESIGN 2

Provides all the necessary tools to produce advanced sheet metal parts and assemblies in one seat. There are also tools to generate production-related drawings, verify the feasibility of creating and manufacturing a part and provide an interface to other, market-leading sheet metal manufacturing tools. It also includes data interfaces to the most frequently used industry standards, including CADAM drawings.

EXTENDED MECHANICAL DESIGN 2

Provides a 3D product creation package perfectly suited to various domains such as Industrial Machinery or Consumer Goods. This includes comprehensive part and assembly design features, as well as associative drawing extraction capabilities. Designers will also find that it has all the 2D drafting features necessary for efficient drawing production.

As a CATIA P2 configuration, XM2 offers advanced 3D orientation features such as the analysis of the degrees of freedom of a component. This enables a quick understanding of how the component is graphically constrained. Basic knowledge capabilities also allow designers to import and use corporate knowledge stored in rule databases to ensure the consistency and quality of their designs.

To meet industrial-scale needs, the configuration has been reinforced with sheet metal design production capabilities and advanced wireframe and surfacing features. Customers benefit from its built-in interoperability with other CATIA V5 solution sets. It is the configuration of choice for existing CATIA V4 customers because it offers integration tools that are compatible with V4 and data interfaces to most frequently used industry standards including CADAM drawings.

COMPOSITES DESIGN 3

Provides all the tools needed to design composites parts for the purposes of a digital mock-up. In addition to its highly productive core product, CATIA – Composites Design 3 (CPD), CD3 delivers advanced mechanical and surfacic tools to underpin the efficient management of design changes. These tools are supported by knowledgeware solutions, which enable the capture and reuse of corporate know-how and standard rule bases. CD3 therefore supports the user throughout the design cycle.

This composites design solution is fully integrated into the CATIA V5 Product Process Resource model that offers a perfect fit with the design-to-manufacturing process and therefore can help companies deliver the right-to-market products.

AEROSPACE SHEET METAL DESIGN 3

Provides all the necessary tools to perform advanced and specific 3D design of sheet metal parts used in the aerospace industry in one seat. It also delivers a full portfolio of productive and innovative Design and Drafting solutions to the user, including applications concerning shape design, image rendering and interfaces. The framework of this solution provides the user with overwhelming product and process integration expertise, where the highest productivity potential is focused on specific aerospace sheet metal processes.

PRODUCTS

ASSEMBLY DESIGN 1

Assembly Design 1 is a P1 product for managing assemblies in a highly productive way. It gives the user the ability to design in assembly context with a user-control associativity, to perform concurrent engineering between the design of the assembly and the design of individual components through a hierarchical assemblies using a top-down or bottom-up approach. Assembly Design 1 establishes mechanical assembly constraints using mouse movements or graphical commands to easily and intuitively snap parts into position.

Through a manual/automatic update choice, the designer can reorder the product structure, drags dynamically parts into position and makes collision and clearance checks. A productive work is provided through a catalogue access for standard parts or assemblies, the access of advanced and powerful assemblies features, automatic exploded view generation and automated BOM generation. Assembly Designers get great time reduction and increased quality. Introducing an intuitive user interface, which is common across Windows® and UNIX®, offers productivity, ease of use, and low training costs.

FUNCTIONAL MODEL PART 1

Functional Molded Part is a flexible and productive 3D modelling package dedicated to the design of molded and plastic parts. The application provides direct access to a collection of intuitive functional features that are the most useful for designing molded parts. For instance, commonly used core and cavity design functional features such as: Extrude, Revolve, Cut, Thicken surface, Rib, Boss, Cutout, Rest, Pocket, Grill, Reinforcement and Shell.

This new design approach enables the user to stay true to the design objectives while the geometric model is generated automatically to meet the requirements. Designs can be built and modified faster and more efficiently while capturing the intelligence necessary to improve the overall understanding of the design.

Instead of managing the design process by means of feature tree and design history, FM1 offers tools that define shape features – such as the core, shell and cavity of a mold. Users can see the resulting molded shape and choose to add incremental features that remain associated to the original feature rather than reflecting in a list of geometric attributes.

PART DESIGN FEATURE RECOGNITION

Part Design Feature Recognition is intended to recognise Part Design feature from an Isolated B-Rep. This product is used to retrieve a comprehensive CATIA data structure (Part Structure) from an Isolated B-Rep Part. The user imports a part and can recover elementary Part Design features.

Part Design Feature Recognition is used to allow better downstream applications integration, to improve Part simplification for tool definition and flexible local design.

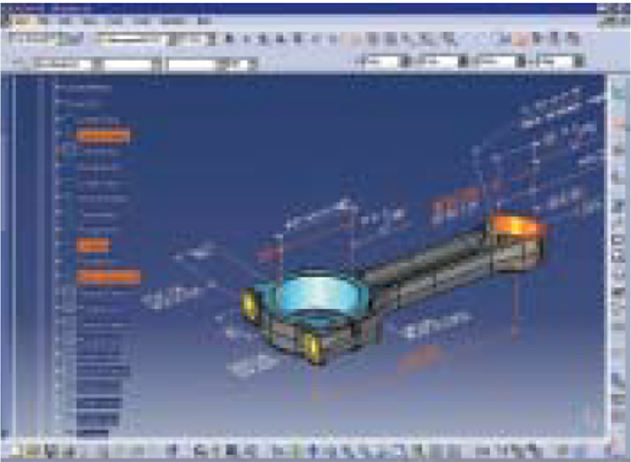

3D FUNCTIONAL TOLERANCING AND ANNOTATION 1

3D Functional Tolerancing and Annotation 1 is a new generation CATIA product addressing the easy definition and management of tolerance specifications and annotations of 3D parts and products. 3D Functional Tolerancing and Annotation 1 product provides an ideal solution for new CATIA customers in small and medium size industries, looking to reduce reliance on 2D drawings and increase the use of 3D as the master representation.

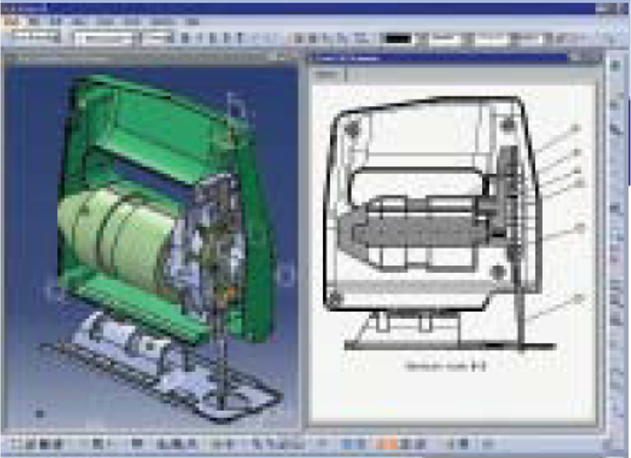

GENERATIVE DRAFTING 1

Generative Drafting for CATIA-P1 allows users to automatically generate associative drafting from 3D mechanical designs and assemblies produced with CATIA Version 5. When combined with Interactive Drafting, the Generative Drafting product 1 benefits both from integrated 2D interactive functionality and from a higher productive environment for drawings dress-up and annotation.

Generative Drafting 1 product offers a flexible and scalable solution accommodating drawing generation requirements for sheetmetal, surface and hybrid parts or assemblies. A drawing creation assistant, or ‘wizard’ simplifies the generation of multiple-view drawings. 3D dimensions can be automatically generated. Designers are able to associate patterns with part material specifications and add post-generation annotations with standards-based dress-up features. Associativity of the drawings to the 3D master representation enables users to concurrently work on their designs and drawings.

HEALING ASSISTANT 1

Healing Assistant product provides users reconciliation and fixing tools to heal parts to be used in downstream applications such as manufacturing, analysis or tooling design. This product helps user checking validity of imported data (surfaces or solids) with regard to V5 modelling criteria, then correcting or improving the topology and the geometry of the analysed objects.

CATIA – Healing Assistant 1 (HA1) is perfectly suited for designers who have to deal with complex parts from various CAD applications and formats. This product allows them to make their Parts ‘V5 compliant’ to be able to reuse components in any V5 applications. The mold and die tooling process is particularly impacted by these advanced capabilities, as tooling is often done by sub-contractors receiving data exported by their OEMs in standard formats such as IGES or STEP. But Healing Assistant is also very useful for data migration, for example, for companies who need to migrate data from their previous CAD (including CATIA V4) to their new CATIA V5 environment.

INTERACTIVE DRAFTING 1

Interactive Drafting is a new generation CATIA product to address 2D design and drawing production requirements. It offers a highly productive, and intuitive, interactive drafting system. It also enriches Generative Drafting with both integrated 2D interactive functionality and with a productive environment for drawings dress-up and annotation.

2D LAYOUT FOR 3D DESIGN 1

2D Layout for 3D Design 1 (LO1) is a new-generation product dedicated to the acceleration of the 3D conceptual design process. It is the only product on the market in which a designer works in a 3D environment with embedded 2D drafting capabilities. During the conceptual phase of a project, LO1 enables the designer to work in a familiar drafting workbench with multi-view capabilities. Users can create layout views containing geometry while getting the most of other key capabilities, such as dimensions, annotations, dress-up,2D components, and constraints. LO1 also incorporates powerful tools for fast and associative 3D geometry creation. Once the design is laid out as 2D sheets and views, the user can print it immediately for review or to generate a complete drawing sheet from this layout and its content. While creating the drawing sheet, the user can add further views to illustrate the design in greater detail. With these capabilities, CATIA – 2D Layout for 3D Design 1 delivers a unique solution that addresses several processes:

- Design 3D models from a 2D conceptual geometry.

- Layout 3D models with full drafting capabilities.

- Create 2D overview layouts quickly in the 3D environment.

- Reuse legacy drawings to start new projects.

Well adapted to both 2D- and 3D oriented users and to 2D customers who want to smoothly start designing in 3D at the conceptual phase, LO1 provides an intuitive environment to capture design intent. Totally integrated into the entire CATIA V5 applications portfolio, LO1 facilitates the preliminary design phase and/or review phases in automotive, fabrication and assembly, and all mechanical industries.

PART DESIGN 1

Part Design 1 provides a basic set of integrated multi-discipline tools for part design. Using the best-in-class feature approach combined with Boolean tools, the user can integrate multiple product views and constraints. Designers choose between single part sketching or working in the assembly context, and benefit from the controlled associativity which promotes a collaborative design.

With clear specification management tools, modifications can be made and the impact assessed quickly. This capability is ideal for multi-user environments and productive iteration. The benefits of this approach are maximised when combined with others V5 applications for styling, mechanical surfaces definition, assembly modelling and downstream documentation.

SHEET METAL PRODUCTION 1

Sheet Metal Production is addressing the manufacturing preparation for sheetmetal parts. In combination with SMD, it provides a solution that covers the design to manufacturing process of sheetmetal parts.

SHEET METAL DESIGN 1

Sheetmetal Design 1 is dedicated to the design of sheet metal parts. Its feature-based approach offers a highly productive and intuitive design environment. It allows concurrent engineering between the folded or unfolded representation of the part.

CATIA – Sheetmetal Design 1 can be cooperatively used with other current or future applications of CATIA Version 5 like part design, assembly design and drawing generation. As sheetmetal design may start from scratch or from an existing solid, communication between suppliers and contractors is empowered.

Sheetmetal Design 1 offers the same ease-of-use and user interface consistency as all CATIA V5 applications to drastically reduce training cycle time and unleash designer creativity.

STRUCTURE DESIGN 1

Structure Design product is an application enabling to simply and quickly creates linear, curved structures, and plates, using standard or user-defined sections. Taking advantage of an optimised user interface, the user can easily create and modify structures thanks to fully associative design in context capability. Moreover, the product includes a parametric catalogue through design tables and it generates user customisable Bills of Materials (BOMs).

It is natively integrated with other CATIA applications for completing the structure design, user will be able, for instance, to perform extensive stress analysis on his structure elements and beams.

TOOLING DESIGN 1

Dedicated to generic and user Tooling Component management, Tooling Design provides to small mold makers a toolset to support the end to end process. This new product covers all productivity features such as positioning and multi instance management and also delivers all needed features for process integration up to drafting and manufacturing (drilling, splitting, propagation of user intent). Moreover, the product includes a rich content through catalogues and samples.

WELDING DESIGN 1

Weld Design is an application addressing welded assemblies. Fifteen weld types (ISO standard) are provided to the user to create welds, part preparation and relevant annotations.

This product addresses Machinery and Tooling industries through advanced welding processes. The creation of the weld in the 3D digital mock-up will allow designer to manage digital pre-assembly, mass inertia, space reservation and drafting annotation.

WIREFRAME & SURFACE 1

Wireframe & Surface is used to create wireframe construction elements during the preliminary design phase. It can also enrich existing 3D mechanical part design with wireframe and basic surface features. Its feature-based approach contributes to a productive and intuitive design environment where design methodologies and specifications can be captured and reused.

ASSEMBLY DESIGN 2

Assembly Design 2 offers a new generation CATIA P2 product for managing assemblies. Assembly Design products integrate with other CATIA Version 5 applications like part design and drawing generation.

Assembly Design 2 establishes mechanical assembly constraints using mouse movements or graphical commands to easily snap parts into position. Assembly Design 2 helps designers managing large, hierarchical assemblies of CATIA V4, V5, VRML or STEP parts using a top-down or bottom-up approach. Parts and sub-assemblies are easily reused in the assembly without data duplication.

Productivity tools like automatic exploded view generation, collision and clearance checking. Automated BOM generation greatly reduce time and increase quality. Flexible sub-assembly gives user the ability to dynamically unlink product structure and mechanical behaviour. This unique command allows to move individual component in the parent assembly or to manage different internal positions of instantiated sub-component.

COMPOSITE ENGINEERING 2

CATIA Composites Engineering Design 2 provides process-oriented tools dedicated to the design of composites parts from preliminary to engineering detailed design. CPE targets the aerospace, automotive, consumer goods, and shipbuilding industry OEMs and their suppliers. Automatic ply generation, exact solid generation, analysis tools such as fibre behaviour simulation and inspection capabilities are just some of the essential components of this product. By enabling users to embed manufacturing constraints earlier in the conceptual design stage, this product shortens the design-to-manufacturing period. Its native integration with the pervasive knowledge and CATIA V5 ease-of-use unveils CPE as a unique composites design solution in the marketplace.

COMPOSITES MANUFACTURING 2

CATIA Composites Design provides process-oriented tools dedicated to the manufacturing preparation of composites parts. CPM targets aerospace, automotive, consumer goods and shipbuilding industry OEMs and their suppliers. With the powerful synchronisation capabilities, CPM is the essential link between engineering design and physical manufacturing, allowing suppliers to collaborate closely with their OEMs in the composites design process. With CPM, manufacturing engineers can include all manufacturing and producibility constraints in the composites design process. This product completes the composites design solution, taking advantage of CATIA V5 architecture: native integration, pervasive knowledgeware capabilities, and ease-of-use.

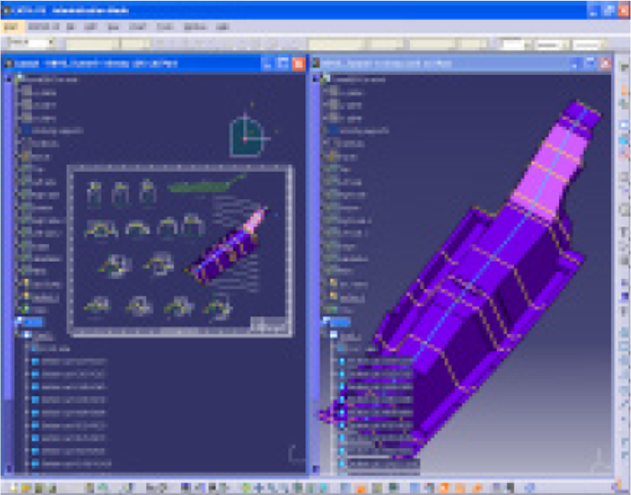

CORE & CAVITY DESIGN 2

Core & Cavity Design allows rapid and cost-effective design of the core and cavity used in mold tooling or manufacturing equipment. This product provides a fast splitting tool that takes a surfacic or solid part and separates it into core and cavity with sliders and loose cores.

Core & Cavity Design is a stand-alone product that determines the ability of a component to be manufactured thanks to technological criteria (moldability). This product allows also the user to fill up technological holes within the core and cavity surfaces, identify the parting lines and to generate the parting surfaces.

CAST & FORGED PART OPTIMIZER 2

Cast & Forged Part Optimizer is an add-on for Part Design 2 (PDG) dedicated to the detailed design of molded & forged parts. Cast & Forged Part Optimizer delivers advanced part design functions that extend the power of dress-up features. These advanced functions are based on innovative and unique patented technology. The powerful auto filtering and advanced draft capabilities provide significant gains in quality and productivity. Dedicated to the casting and forging process, this add-on is totally integrated into the entire CATIA V5 application portfolio. Users can finish their design with CATIA – Part Design 2 (PDG), avoiding the need to make repetitive use of surface and wireframe operations. The user benefits from improved robustness, higher productivity (fewer clicks), greater stability following design changes; and a reduction in prerequisite learning activity.

FUNCTIONAL MOLDED PARTS 2

Functional Molded Parts is a new generation product for designing cast, molded, and forged parts and related tooling with unmatched productivity and flexibility Its history-free functional design approach for defining the complete functional specification for both parts and their associated tooling makes FMP a breakthrough product for reducing the design-to-manufacturing cycle.

Building on the foundation of functional part definition, FMP accelerates time-to-market by intelligently understanding the geometrical and tooling definition from a designer’s functional concept. By taking advantage of the unique CATIA V5 geometrical modeller and the process coverage of complementary CATIA products, companies can realise significant efficiency savings. Freeing the designer from the constraints of history-based design, the order in which features are created has no impact on the design itself.

3D FUNCTIONAL TOLERANCING AND ANNOTATION 2

3D Functional Tolerancing and Annotation 2 is a new generation CATIA product addressing the easy definition and management of tolerance specifications and annotations of 3D parts and products. The intuitive interface of 3D Functional Tolerancing and Annotation product provides an ideal solution for new CATIA customers in small and medium size industries, looking to reduce reliance on 2D drawings and increase the use of 3D as the master representation. 3D annotations can be extracted, using the annotation plane concept in CATIA – Generative Drafting products. Besides syntactic and semantic verification command allows the user to check the correctness of all the annotations of the active product or part regarding to the standard used.

Finally, the 3D annotations can be reviewed using ENOVIA VPLM – DMU Dimensioning & Tolerancing 1 product (DT1) or DELMIA – DMU Dimensioning& Tolerancing Review 2 product (MTR), which offers comprehensive tools for interpretation of annotations and tolerances on specific areas of the design or across the complete digital mock-up.

GENERATIVE DRAFTING 2

Generative Drafting for CATIA-P2 is a new generation CATIA product which allows users to automatically generate associative drafting from 3D mechanical designs and assemblies produced with CATIA Version 5. When combined with Interactive Drafting, the Generative Drafting 2 product benefits both from integrated 2D interactive functionality and from a higher productive environment for drawings dress-up and annotation.

Generative Drafting 2 product offers a flexible and scalable solution to create associative drawings from 3D mechanical designs, surfaces, hybrid parts and assemblies created with CATIA Version 4 or Version 5. 3D dimensions can be automatically generated with control over their placement. Designers are able to add post-generation annotations with standards-based dress-up features. Associativity of the drawings to the 3D master representation enables users to concurrently work on their design and drawings.

PART DESIGN 2

Part Design 2 extends the basic set of integrated multi-discipline tools within CATIA Part Design 1 (PD1) to provide unique industry features. Part Design 2 supports all the demanding design applications, such as powertrain, plastic parts, and aerospace structure. Based on a template approach, users can proliferate in a simple manner dedicated complex features, optimising time design and iteration. Enriching a knowledge template repository, they can use the old project as best practices for the coming ones. Due to V5 integration, those templates inputs shared a common multi-disciplinary approach such as tooling specifications, analysis, manufacturing constraints, usability.

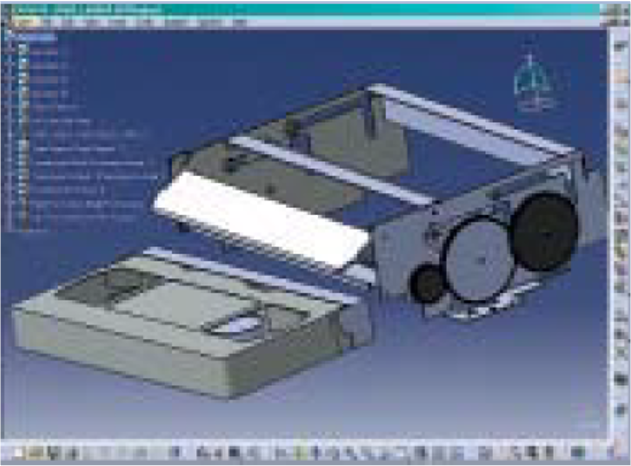

MOLD TOOLING DESIGN 2

CATIA Mold Tooling Design product manages mold tool definitions. It can be cooperatively used with other current or future design, simulation and manufacturing applications of CATIA Version 5 to offer high productivity. It allows rapid, cost effective creation of mold tooling for the plastic injection process thanks to the use of predefined components from standard catalogues with specific functionality to define mold components and instantiations.

A mold designer can benefit from a dedicated workbench to support all their tasks, like mold base definition, component instantiation, injection and cooling feature definitions, and others which are necessary to define a complete mold tooling.

Mold designers can generate dedicated and customisable Bills of Materials (BOM’s) including specific attribute of the mold (material, heat treatment) and automatic nomenclature from the component’s configuration. Textual format, HTML orXLS (Excel) formats can be generated interactively. The BOM can also be based on user-defined attributes.

SHEETMETAL DESIGN 2

Sheetmetal Design 2 is a new generation CATIA product dedicated to the design of sheetmetal parts. Its feature-based approach offers a highly productive and intuitive design environment. It allows concurrent engineering between the folded or unfolded representation of the part.

Sheetmetal Design 2 can be cooperatively used with other current or future applications of CATIA Version 5 like part design, assembly design and drawing generation. As sheetmetal design may start from scratch or from an existing solid, communication between suppliers and contractors is empowered. It includes many standard design features, such as stiffeners, stamped shapes and swept features.

Sheetmetal Design 2 offers the same ease of use and user interface consistency as all CATIA V5 applications to drastically reduce training cycle time and unleash designer creativity. It also provides multiple interoperability functions with CATIA V4 sheetmetal products.

AEROSPACE SHEET METAL DESIGN 3

Generative Aerospace Sheetmetal Design is a product dedicated to the definition of sheetmetal parts used in the aerospace industry (hydro-pressed or break-formed). It enables the capture of company knowledge, including design, and manufacturing constraints.

Generative Aerospace Sheetmetal Design product is based on feature modelling techniques, using a pre-defined set of features used for sheetmetal parts designed in the aerospace industry.

Based on both specification-driven and generative approaches, this product will allow typical hydro-formed aerospace parts to be easily specified, the system taking care of creating both 3D and flattened part geometry. Where such parts are designed or modified with basic modelling tools within hours or days, this product allows same result to be achieved in minutes.

CATIA Generative Aerospace Sheetmetal Design provides an interactive function to design sheetmetal parts in a very intuitive way, taking manufacturing constraints into accounts. It provides the flat pattern of the sheetmetal part, and allows easy incremental design (from preliminary to detailed stages) and modification both in 3D and flattened conditions.

Whenever initial specifications are changed (for example, the aircraft skin on which a frame has been designed is modified), this product will allow new part to be automatically rebuilt, based on new specifications.

COMPOSITE DESIGN 3

Composites Design is an advanced composites process centric solution that allows manufacturers, from aerospace to automotive or consumer goods companies, to reduce the time needed to design composites parts. It delivers tools to cover both the preliminary and detailed design phases while taking into account, even at the concept stage, the product’s requirements and its manufacturability.

Composites Design uniquely delivers a powerful composites design solution with all the advantages of the CATIA V5 architecture: native integration, pervasive knowledgeware capabilities, and CATIA V5’s ease-of-use.

OTHER CONFIGURATIONS & PRODUCTS ARE AVAILABLE FOR:

- Shape Design and Styling Products

- Product Synthesis

- Equipment and Systems

- Analysis

Contact us and we will share with you our experiences with satisfied CATIA users.